electrical discharge machining working principle

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. It is suitable for thermoelectric.

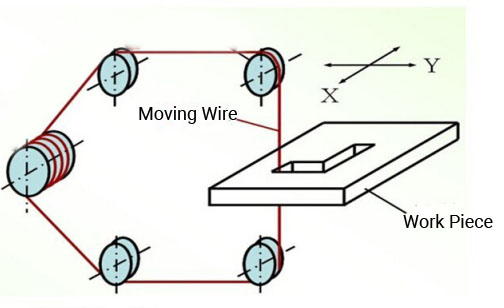

Wire Edm Wire Electro Discharge Machining Engineeringclicks

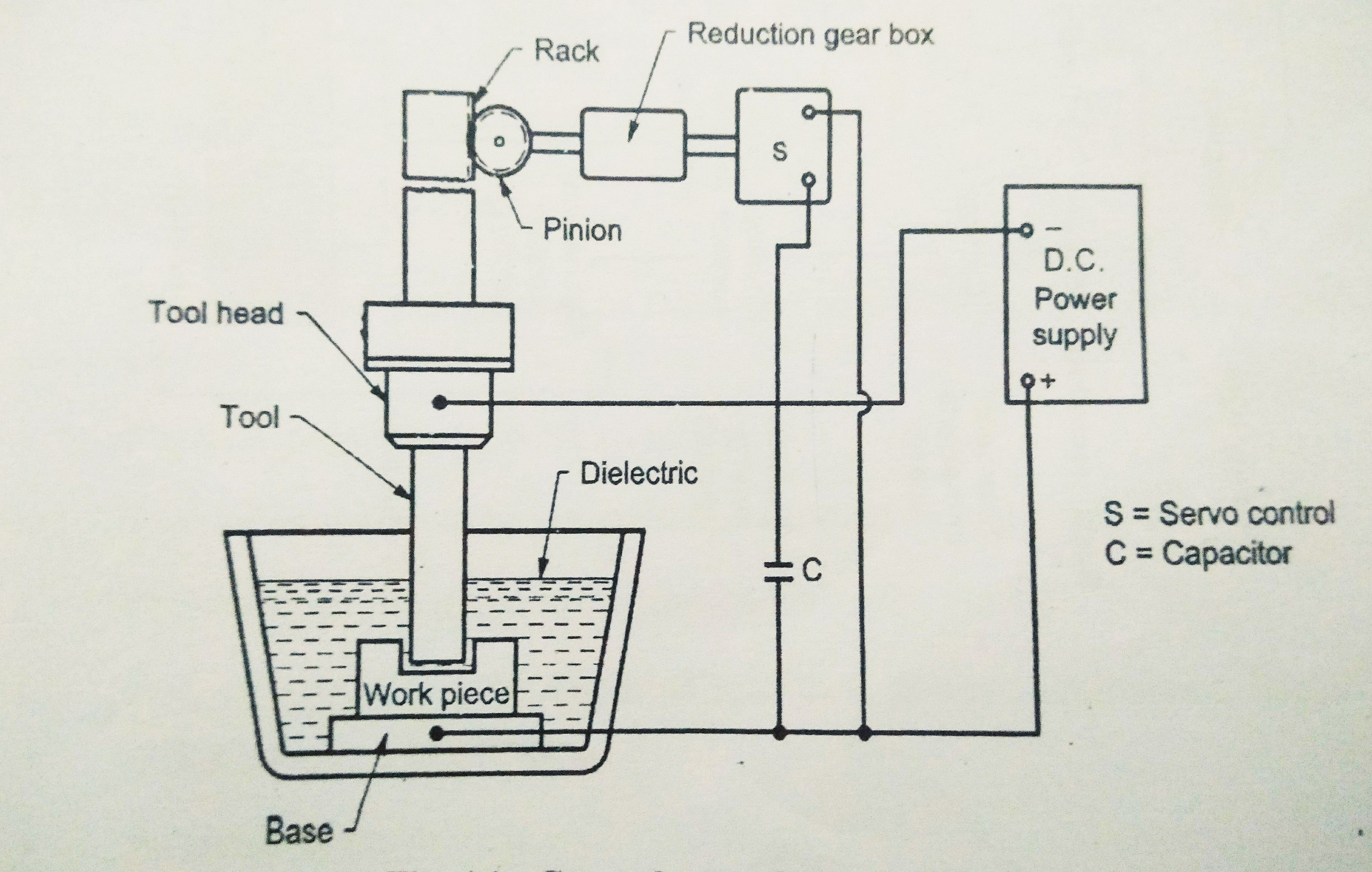

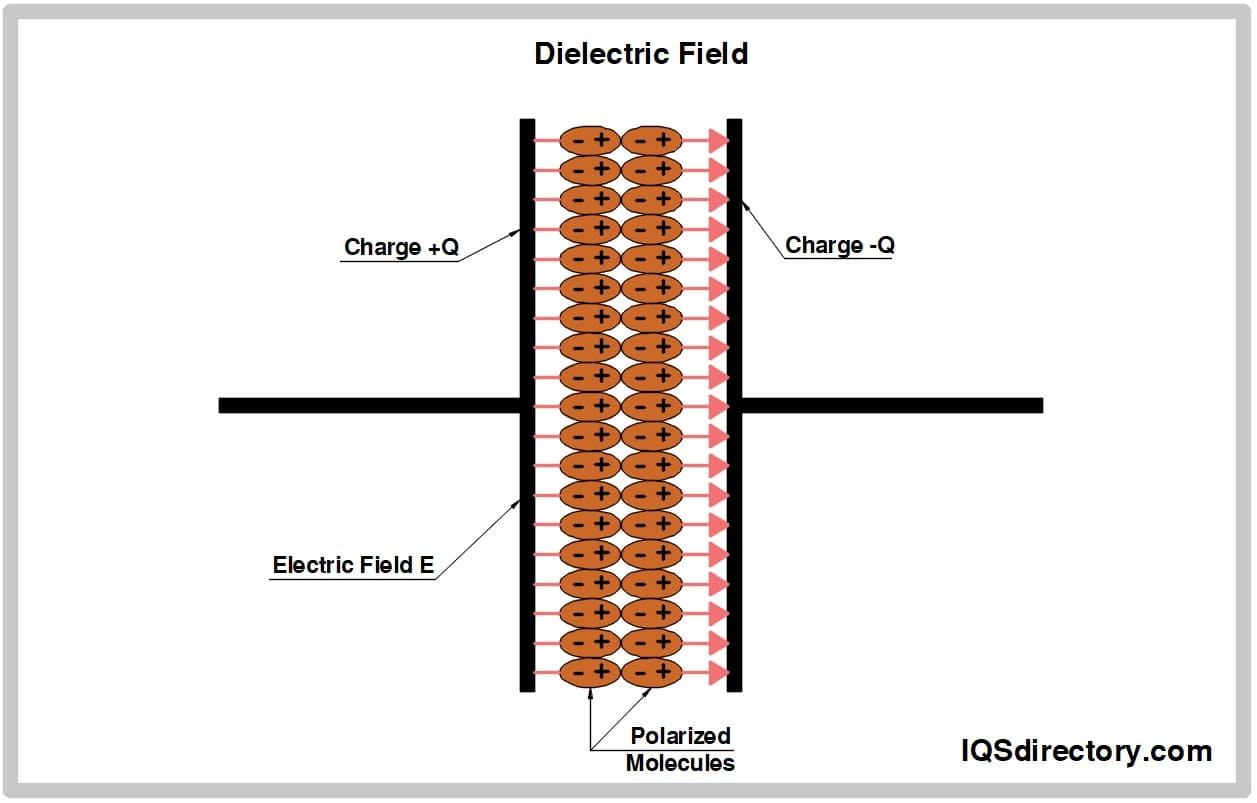

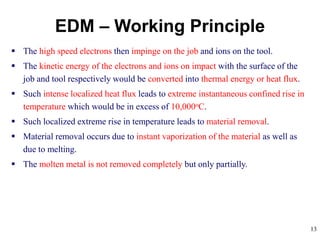

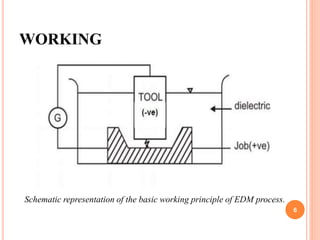

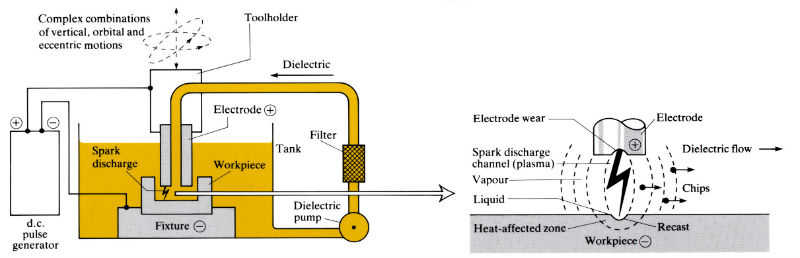

Electrical Discharge Machining Working Principle Electrical discharge machining is based upon the principle of electro discharge erosion EDE effect of electric sparks occurring between.

. The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion. Working of Electric Discharge Machining-Here is a working explanation of EDM Process step by step-As the pulse of DC electricity reaches the electrode and applies an intense electrical field. Ad Buy Electrical Products at Grainger.

Access To Experts 247 Knowledgeable Support. GoldenSources meta data and data lineage capabilities are ideal to create a shared architecture for compliance with the BCBS 239 principles for risk data aggregation and risk. Principle and Manufacturing Applications Manufacturers often turn to electrical discharge machining EDM whenever traditional machining methods reach.

Makino EDMs have a streamlined and efficient interface that helps work get done faster. Low Prices on Millions of Books. Ad Makino is the world leader in Electrical Discharge Machining.

An Overview of Electrical Discharge Machining EDM Electrical discharge machining EDM is a process of removing material by exposing it to reoccurring controlled. Ad Free 2-Day Shipping with Amazon Prime. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a process of metal removal based on the principle of erosion of metals by.

In our analysis H- amount of heat input cal θ temperature C t time sec kthermal conductivity calcm-sec-C α thermal diffusivity cm 2 sec t d discharge duration sec. Electrical discharge Machining Working Principle. Ad Free 2-Day Shipping with Amazon Prime.

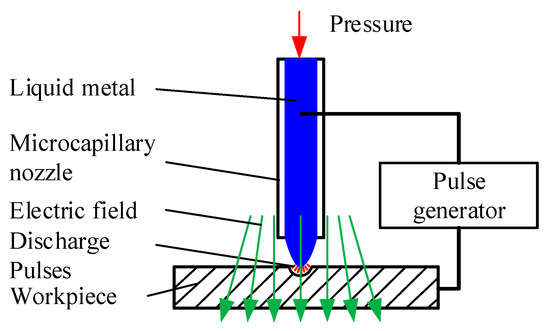

Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the. For quality parts delivered on time choose Xometry cnc machining services.

Explanation of EDMAudio. Electrical discharge machining is a heat-based subtractive manufacturing process. Low Prices on Millions of Books.

Working Principle of Electrical Discharge Machining. It consists of an electric power supply the dielectric medium the tool workpiece and servo control. Ad Full suite of CNC machining services including the latest in wire EDM machining.

It converts electrical discharge into thermal energy that melts or vaporizes excess. The workpiece is connected to the.

How Does A Wire Electrical Discharge Machining Work Neva

What Is Wire Edm Electrical Discharge Machining Xact

Edm Machining Components Types Applications And Advantages

Ppt Electric Discharge Machining Powerpoint Presentation Free Download Id 5371746

Electrical Discharge Machining How Edm Machine Works

What Is Edm Machining Wire Edm 101 Sans

Electric Discharge Machining English Youtube

Electrical Discharge Machining

Micromachines Special Issue Micro Electro Discharge Machining Principles Recent Advancements And Applications

Electrical Discharge Machining Edm Process Explained

Fig Working Principle Of Edm Process Download Scientific Diagram

Electrical Discharge Machining

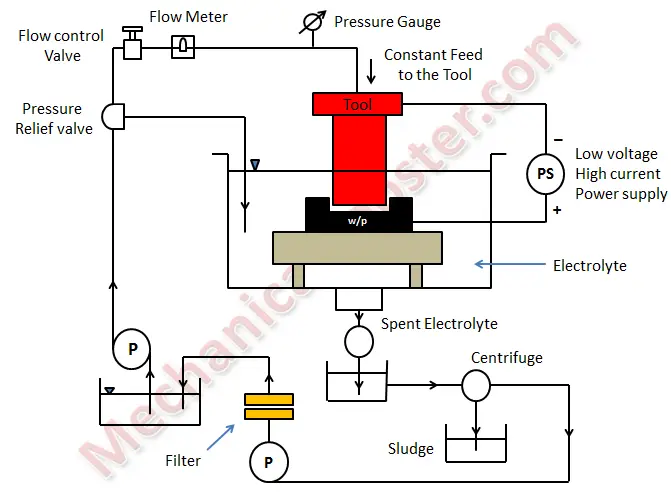

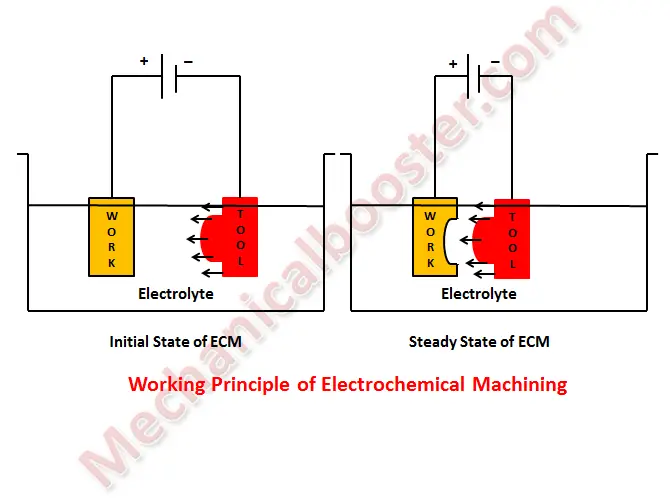

Electrochemical Machining Ecm Working Principle Equipment Advantages And Disadvantages With Application Mechanical Booster

Gate Ese Electrical Discharge Machining In Hindi Offered By Unacademy

Electrochemical Machining Ecm Working Principle Equipment Advantages And Disadvantages With Application Mechanical Booster

Electrical Discharge Machining Process

Principle Of Electric Discharge Machining Download Scientific Diagram

Electrical Discharge Machining Edm And Grinding Edg Openlearn Open University